PRECIMETER is specialized in the production of sensors dedicated to the continuous measurement of the level of molten metals. Therefore they can ensure workers safety, measurement accuracy and life of the sensor.

Precimeter has many installations all over the world and can provide sensors and actuators for the automation of every type of casting machine:

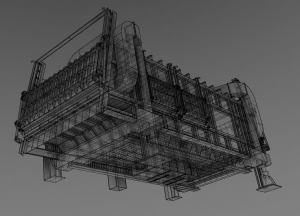

- Casting machines: it's possible to fully automate casting machines. Consequently it is possible to achieve many advantages such as:

a) Workers safety (the workers act inside a room and not close to the casting machine);

b) By automating the start, the quality is not dependent on the operator skill and once the optimal parameters of casting are set, all castings are identical;

c) Having each casting equal to the previous gives the possibility to fine tune the casting parameters and further improve the quality;

d) For example, it is possible to work with a lower level of the metal in the die, resulting in a thinner cortical region, more quality and losses reduction in the following stages of the process;

e) It is possible to calculate the metal needed for a given ingot length and automatically control the furnace, the degasser and the casting machine so as to cast the exact quantity of metal necessary.

Click here to download a brochure

- Laser ProH/ProLAD:

The Digital Camera Sensor Family ProH from Precimeter combines high performance laser triangulation with all the control functions you need to maintain an accurate molten metal level. The patented digital camera technology in the Precimeter sensors results in very high performance and accuracy. This enables the use of Laser Class II, which means that no special safety measures are required. The advanced technology makes possible to give stable readings even when the material reflectivity changes dramatically and in harsh conditions like steam and smoke. The built in PI controller eliminates the need of an external industrial controller. This reduces the system cost and set up time.

The advantages are:

• No safety measures required, no yearly eye examination, no laser officer required.

• Stable readings even in difficult environments.

• Laser class II approved

• Easy to install

• Compact design

• Metal Level Control systems adapted to our actuators and sensors are availiable.

• PC Software gives access to all sensor parameters.

Click here to download a brochure

- PLPR:

As an alternative to electrode scanning, Precimeter offers a purpose-built proximity probe to allow positioning of the exact operating point

of the spoon.

The advantages are:

• No contact with the melt

• Less down time than electrodes

• No robot arm repairs

• No oxide adherence

• No corrosion

• Accurate approach of the point of reference

click here to download a brochure

- CLP:

The submersible CLP from Precimeter is a high tech product. It works in the submerged condition with an appropriate protective tube at a melt temperature of over 800°C and can therefore also be used in closed systems without forced air cooling. The CLP is a system that directly registers the exact level in the molten metal through a protective tube. With an airtight adapter available from Precimeter the probes can also be used in closed systems with low pressure castings.

Click here to download a brochure

- RP:

The ring probe was developed to measure the metal inside a ceramic riser tube in low-pressure casting systems. The ring probe is pushed over the tubing, so that the injection process can be started with rising metal from a preadjusted reference point.

Click here to download a brochure